Contact Us

E-Mail:

zf_zr@126.com

Service Phone Number:

0797-8304789

Company Address:

Plot A-2 of Ganzhou Comprehensive Bonded Zone, Gangbian Avenue, Ganzhou Economic and Technological Development Zone, Ganzhou City, Jiangxi Province

製品の仕様・技術的な内容に関するお問い合わせ

TEL:(0086+18942280710)日本語が話せる

Product Center

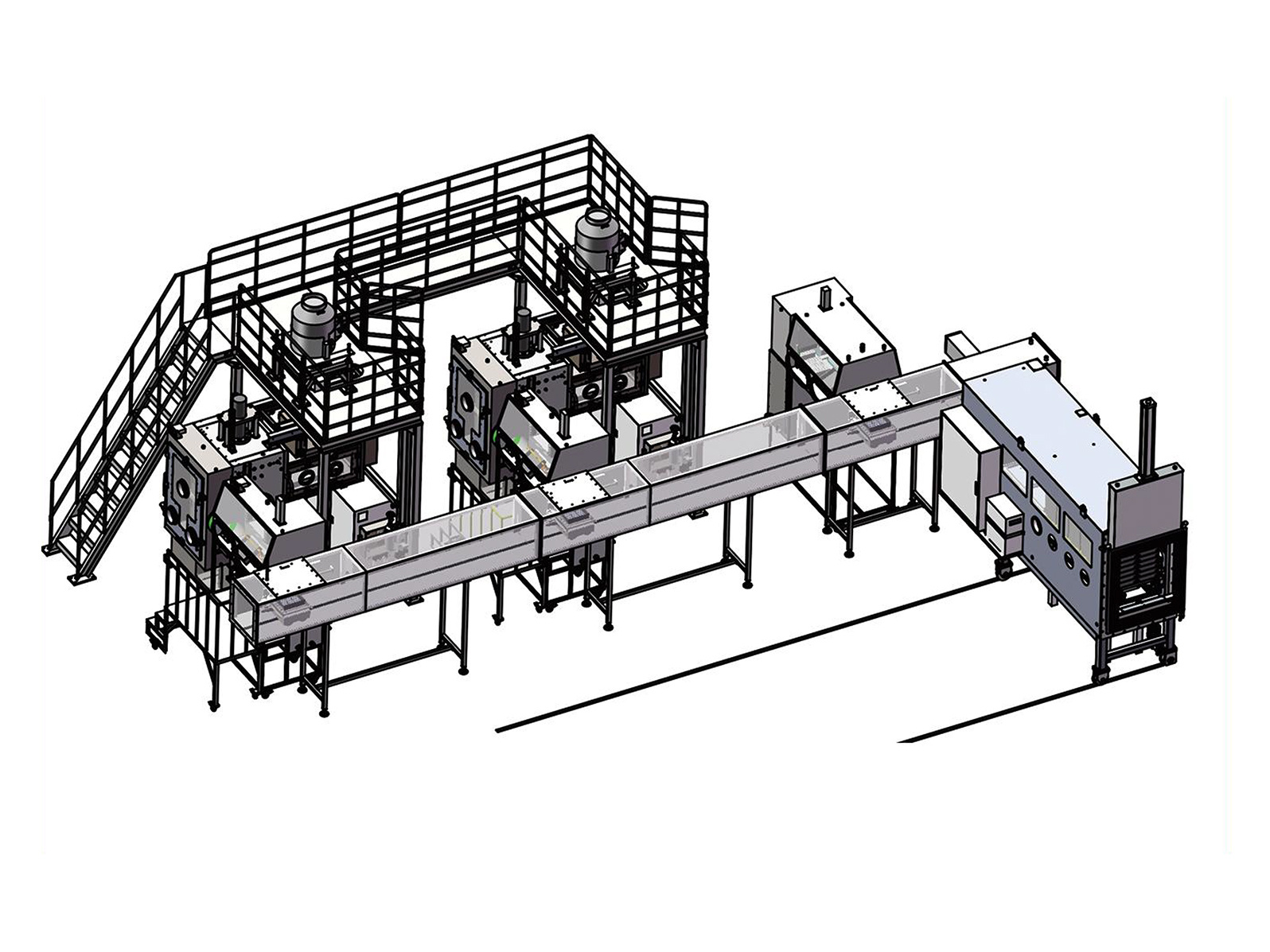

Unmanned One-Time Molding Modular Combination Production Line Series

1: Modular combination of press and code box compartment; 2: AGV material flow

3: Split four column guidance, high precision; 4: Oil cooled electromagnet, efficient and energy-saving

5: Stable and efficient IGBT charging and demagnetization system; 6: Integrated structure, easy and fast installation

7: Simultaneously supporting both isostatic pressing and non isostatic pressing processes; 8: Highly automated, automatic code magnetic block stone ink cartridge

9: Mold installation is simple and fast; 10: Automatic oxygen exhaust system, saving nitrogen

11: Automatic spraying of mold release agent and automatic powder production; 12: High precision digital molding system, supporting remote monitoring

13: Automatic servo adjustment protection demolding; 14: One time molding without vacuum packaging and isostatic pressing

3: Split four column guidance, high precision; 4: Oil cooled electromagnet, efficient and energy-saving

5: Stable and efficient IGBT charging and demagnetization system; 6: Integrated structure, easy and fast installation

7: Simultaneously supporting both isostatic pressing and non isostatic pressing processes; 8: Highly automated, automatic code magnetic block stone ink cartridge

9: Mold installation is simple and fast; 10: Automatic oxygen exhaust system, saving nitrogen

11: Automatic spraying of mold release agent and automatic powder production; 12: High precision digital molding system, supporting remote monitoring

13: Automatic servo adjustment protection demolding; 14: One time molding without vacuum packaging and isostatic pressing

1. Adopting a left in and right out external circulation method, the cooling speed is accelerated and the cooling power is reduced< br>

2. Adopting a square furnace structure improves the uniformity of the temperature zone. By doubling the thickness of the insulation layer and selecting high-quality insulation materials with a thermal conductivity of only 0.07, energy consumption can be reduced by more than 50%< br>

3. Adopting a new type of column fin radiator, integrated with the return air duct, saves space, improves air flow, and enhances heat exchange efficiency.

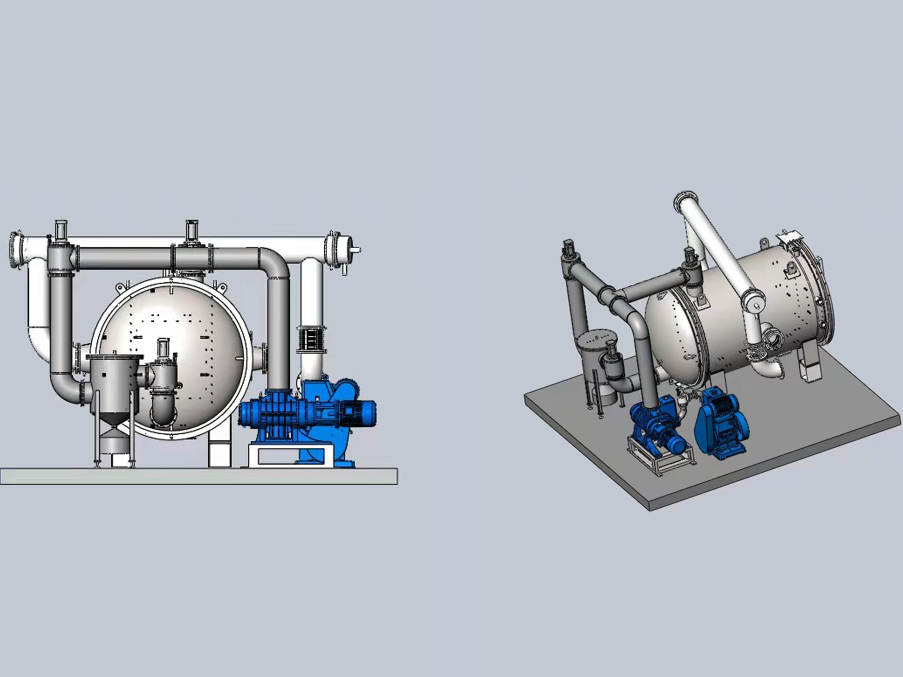

XZHD-600H Rotary Hydrogen Decrepitation Furnace

1. High degree of automation, pure horizontal work, no need for tipping, improved reliability and operability

2. Independent filter, electric furnace moves on the platform guide rail, with wide space

3. The cooling speed is accelerated, reducing thermal radiation, improving the working environment, and the production efficiency is high, uniform, and safe. It is used for neodymium iron boron (titanium alloy) hydrogen crushing and dehydrogenation processes.