Contact Us

E-Mail:

zf_zr@126.com

Service Phone Number:

0797-8304789

Company Address:

Plot A-2 of Ganzhou Comprehensive Bonded Zone, Gangbian Avenue, Ganzhou Economic and Technological Development Zone, Ganzhou City, Jiangxi Province

製品の仕様・技術的な内容に関するお問い合わせ

TEL:(0086+18942280710)日本語が話せる

Product Center

Pure Electric Magnetic Field Forming Press Series

3: Stable and efficient IGBT charging and demagnetization system; 4: Integrated structure, easy and fast installation

5: High production efficiency, conventional block CT is less than 30 seconds; 6: Highly automated, only requiring vacuum packaging

7: Mold installation is simple and fast; 8: Automatic oxygen exhaust system, saving nitrogen

9: Automatic spraying of mold release agent and automatic powder production; 10: High precision pure electric digital molding system, supporting remote

11: Automatic servo adjustment protection demolding; 12: All aluminum alloy vacuum packaging system

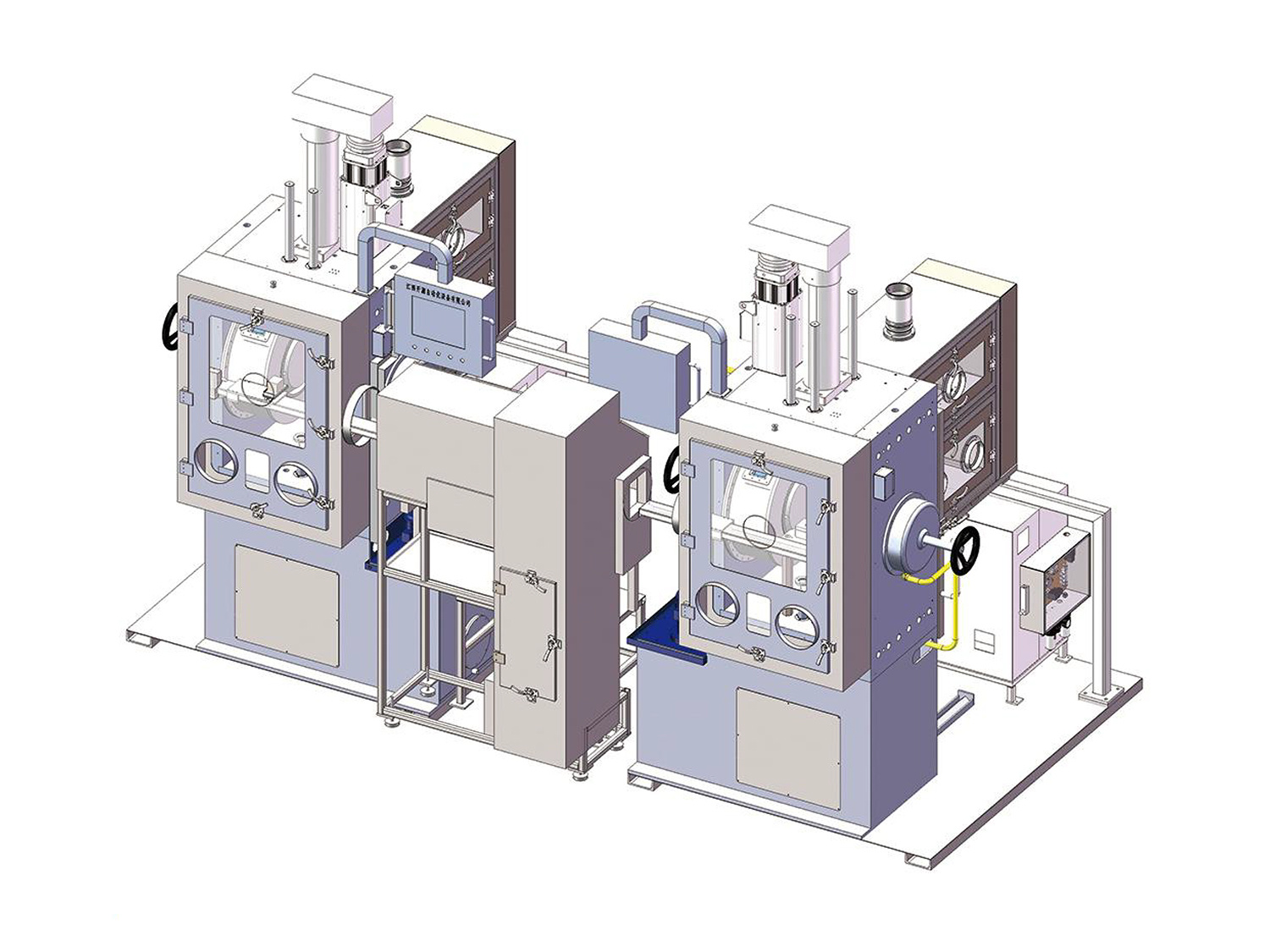

Fully Electric One To Two Magnetic Field Press

3: Stable and efficient IGBT charging and demagnetization system; 4: Integrated structure, easy and fast installation

5: High production efficiency, 4 molds per minute; 6: Highly automated, only requiring vacuum packaging

7: Mold installation is simple and fast; 8: Automatic oxygen exhaust system, saving nitrogen

9: Automatic spraying of mold release agent and automatic powder production; 10: High precision digital molding system, supporting remote monitoring

11: Automatic servo adjustment protection demolding; 12: Aluminum alloy vacuum packaging system

13: Compact structure saves space; 14: Four column guidance, high molding accuracy

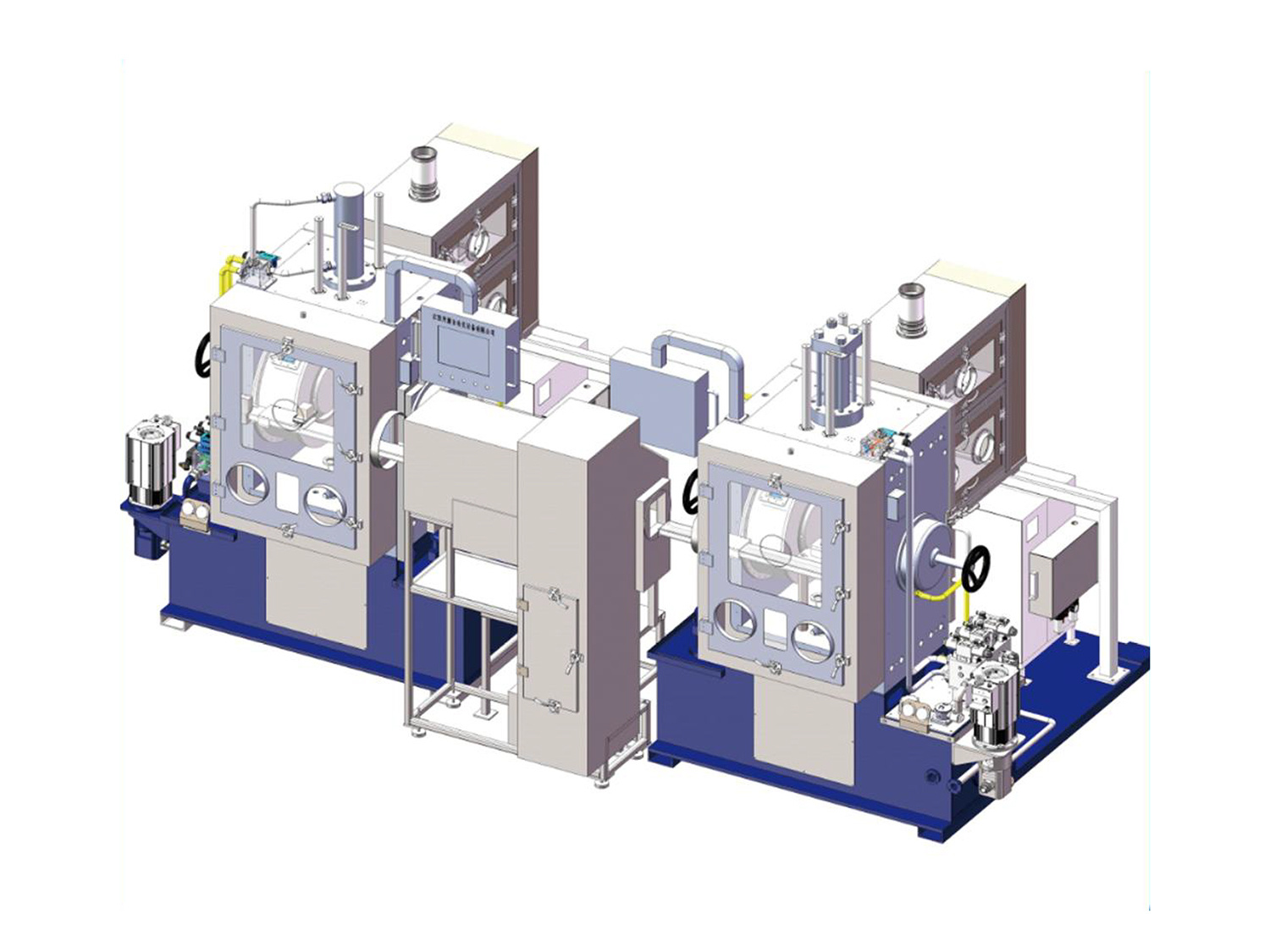

Oil Electric Servo One To Two Magnetic Field Press

3: Stable and efficient IGBT charging and demagnetization system; 4: Integrated structure, easy and fast installation

5: High production efficiency, 4 molds per minute; 6: Highly automated, only requiring vacuum packaging

7: Mold installation is simple and fast; 8: Automatic oxygen exhaust system, saving nitrogen

9: Automatic spraying of mold release agent and automatic powder production; 10: High precision digital molding system, supporting remote monitoring

11: Automatic servo adjustment protection demolding; 12: Aluminum alloy vacuum packaging system

13: Compact structure saves space; 14: Four column guidance, high molding accuracy

One To Two Automatic Code Box Series

3: Split four column guidance, high precision; 4: Oil cooled electromagnet, efficient and energy-saving

5: Stable and efficient IGBT charging and demagnetization system; 6: Integrated structure, easy and fast installation

7: High production efficiency; 8: Highly automated, automatic code magnetic block

9: Mold installation is simple and fast; 10: Automatic oxygen exhaust system, saving nitrogen

11: Automatic spraying of mold release agent and automatic powder production; 12: High precision digital molding system, supporting remote monitoring

13: Automatic servo adjustment protection demolding; 14: One time molding without vacuum packaging and isostatic pressing

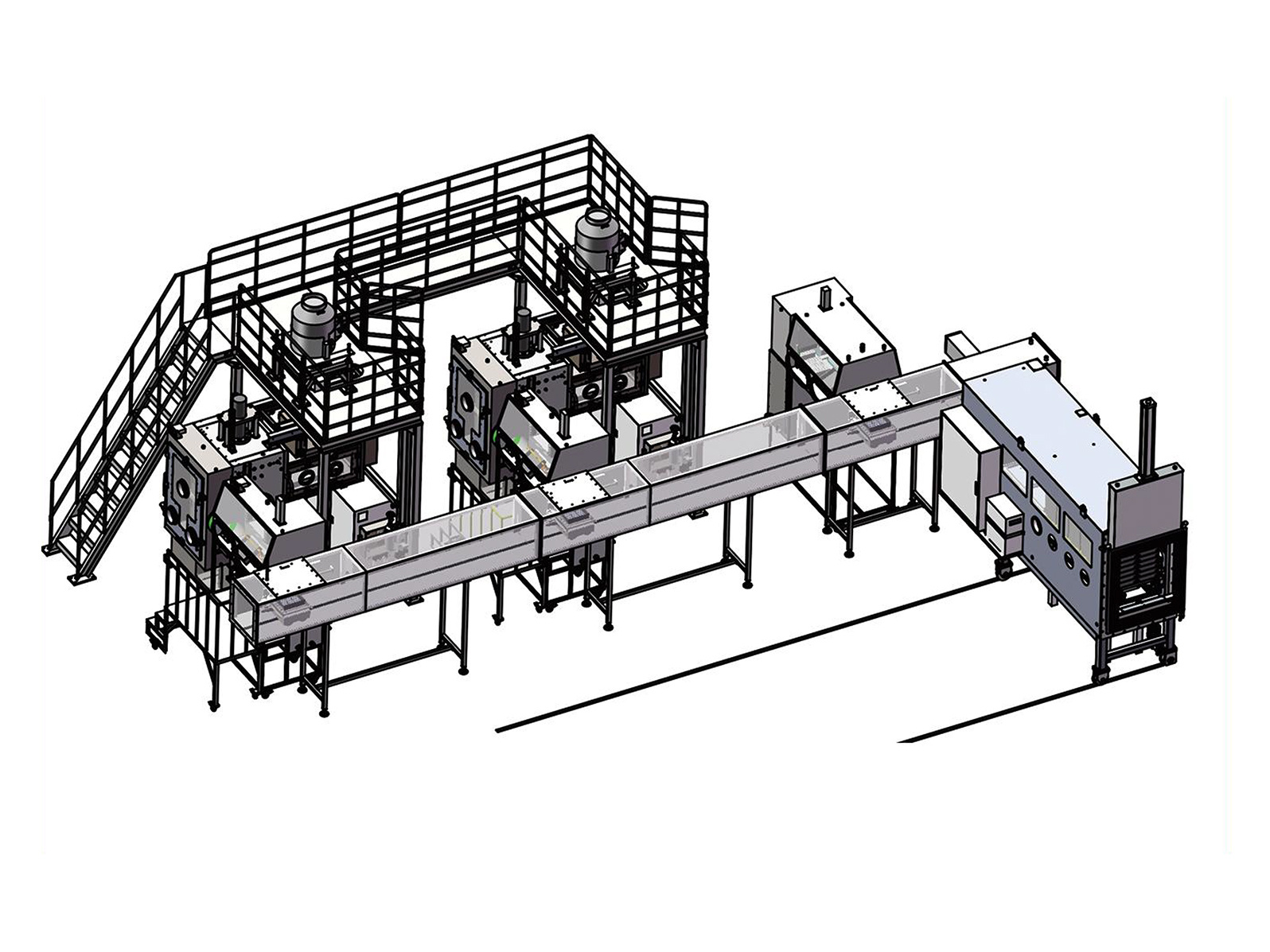

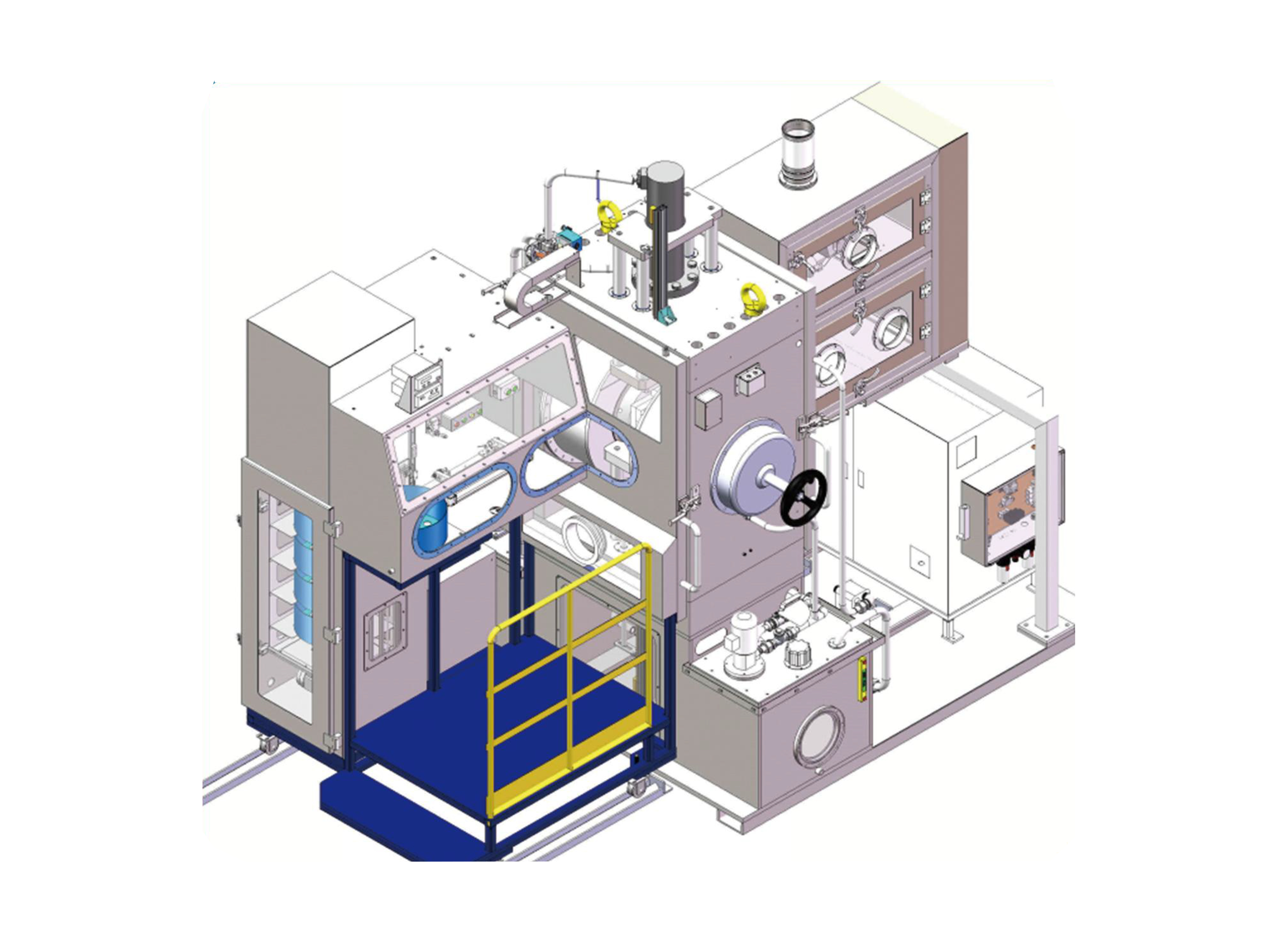

Unmanned One-Time Molding Modular Combination Production Line Series

3: Split four column guidance, high precision; 4: Oil cooled electromagnet, efficient and energy-saving

5: Stable and efficient IGBT charging and demagnetization system; 6: Integrated structure, easy and fast installation

7: Simultaneously supporting both isostatic pressing and non isostatic pressing processes; 8: Highly automated, automatic code magnetic block stone ink cartridge

9: Mold installation is simple and fast; 10: Automatic oxygen exhaust system, saving nitrogen

11: Automatic spraying of mold release agent and automatic powder production; 12: High precision digital molding system, supporting remote monitoring

13: Automatic servo adjustment protection demolding; 14: One time molding without vacuum packaging and isostatic pressing

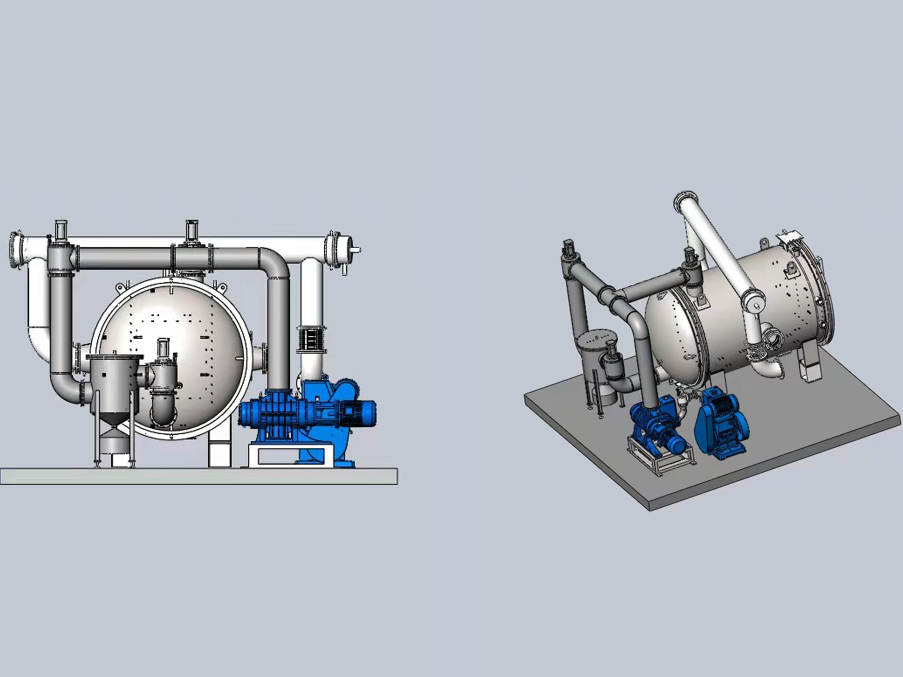

XZHD-600H Rotary Hydrogen Decrepitation Furnace

Fully Automatic Magnetic Field Press Machine

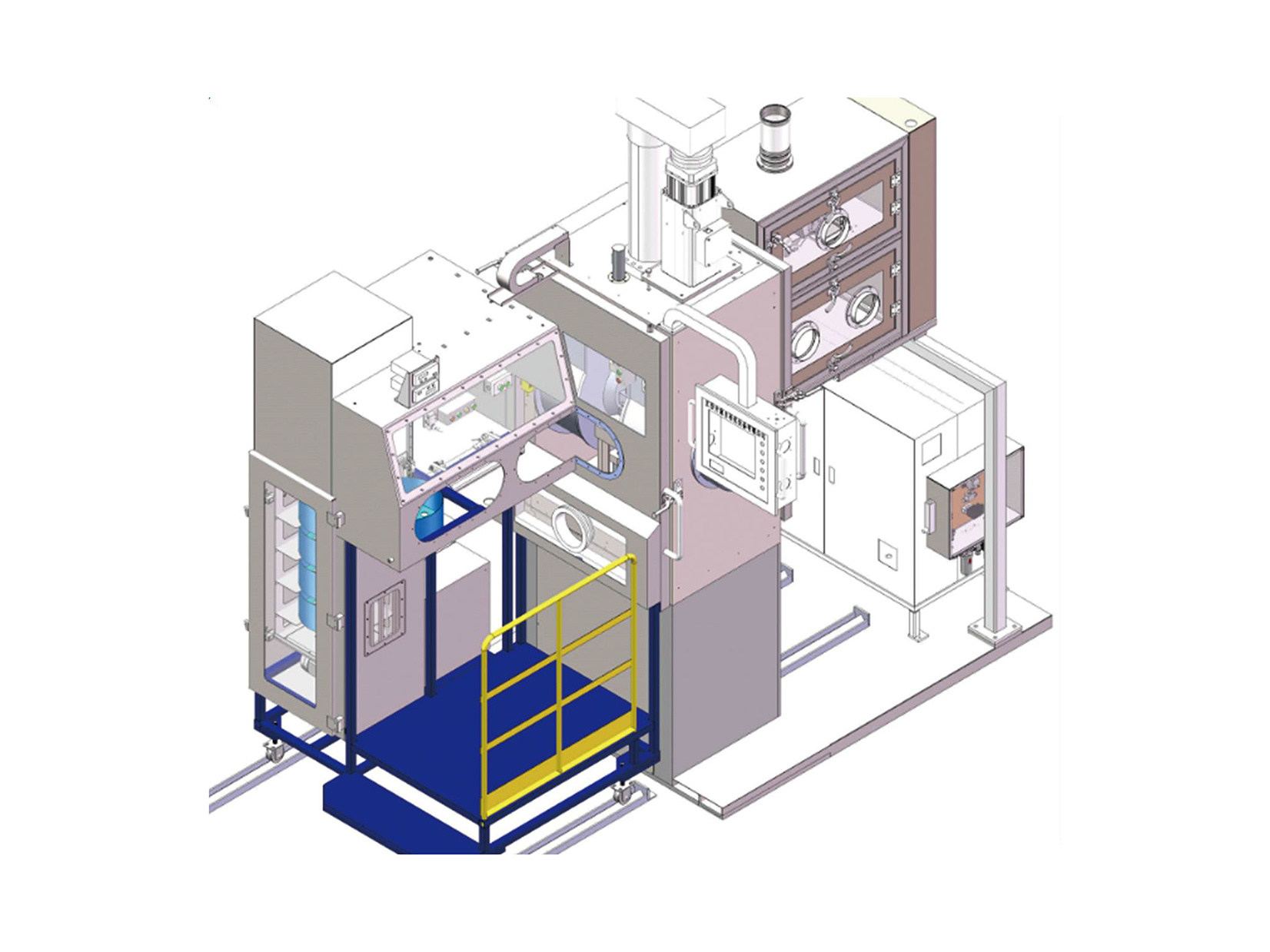

Fully Automatic Magnetic Field Forming Press

3: Stable and efficient IGBT charging and demagnetization system; 4: Integrated structure, easy and fast installation

5: High production efficiency, conventional block CT is less than 30 seconds; 6: Highly automated, only requiring vacuum packaging

7: Mold installation is simple and fast; 8: Automatic oxygen exhaust system, saving nitrogen

9: Automatic spraying of mold release agent and automatic powder production; 10: Oil electric servo energy-saving, supports remote monitoring

11: Automatic servo adjustment protection demolding; 12: All aluminum alloy vacuum packaging system

Fully Automatic Magnetic Field Press Machine